What is it about?

Using some sort of HF pretreatment is standard when passivating Si. The article compares how a 3 minute HF pretreatment affects the passivation properties relative to using no pretreatment at all. We find that samples where no pretreatment is used exhibit significantly improved passivation properties, which we argue could be due to to Al-incorporation in the SiOx that is grown during the first cycles of the Al2O3 deposition.

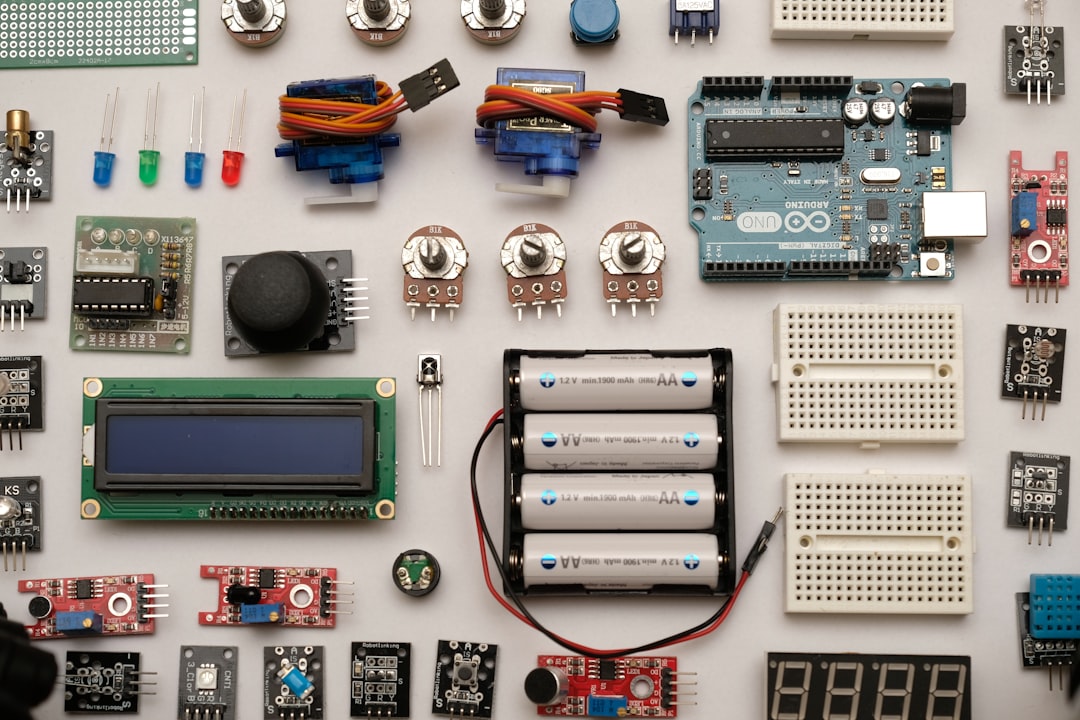

Featured Image

Photo by Marian Kroell on Unsplash

Why is it important?

In order to meet growing demand for renewable energy, a dramatic increase in photovoltaic installations is required. Surface passivation is critical to reach high solar cell efficiencies for thin solar cells and for any nano-/micro-scale device relying on collection of mobile charge carriers. The article demonstrates a method to achieve an excellent level of surface passivation without using HF, which could thus improve solar cell efficiency at a potentially reduced cost.

Perspectives

I think this work provides some enhanced understanding of the Si-SiOx-Al2O3 interface and how this should be tailored in order to achieve ideal surface passivation. The article may also spark some interest in investigating similar interfaces and comparing other pretreatments (e.g. shorter HF-dip durations, different native oxide thicknesses, etc.).

Michael Getz

Universitetet i Oslo

Read the Original

This page is a summary of: Effect of the native oxide on the surface passivation of Si by Al2O3, Journal of Applied Physics, May 2021, American Institute of Physics,

DOI: 10.1063/5.0051215.

You can read the full text:

Contributors

The following have contributed to this page