What is it about?

In this study, the effect of different tool geometry, tool material, different cutting conditions and parameters on the cutting temperature was investigated experimentally. All factors that may cause necrosis during the drilling process were tried to be determined. Femur bones of the cattle that were alive 12 hours ago were used in the experiments and the cutting temperature was determined experimentally at the points very close to the puncture site. According to the results obtained, speed is the parameter that most affects the cutting temperature. Increasing feed rate causes a decrease in cutting temperature. Drilling holes with pecking technique contributes to a significant reduction in temperature in the cutting zone. The pecking technique significantly reduces the cutting temperature. Saline fluid applied at low flow causes the drill flutes to clog while saline fluid applied at the flow rate of 0.04 l/min lowers cutting temperature. Lower cutting temperatures were observed in drill bits made of AISI-316L material. Also, the effects of drill geometry are included.

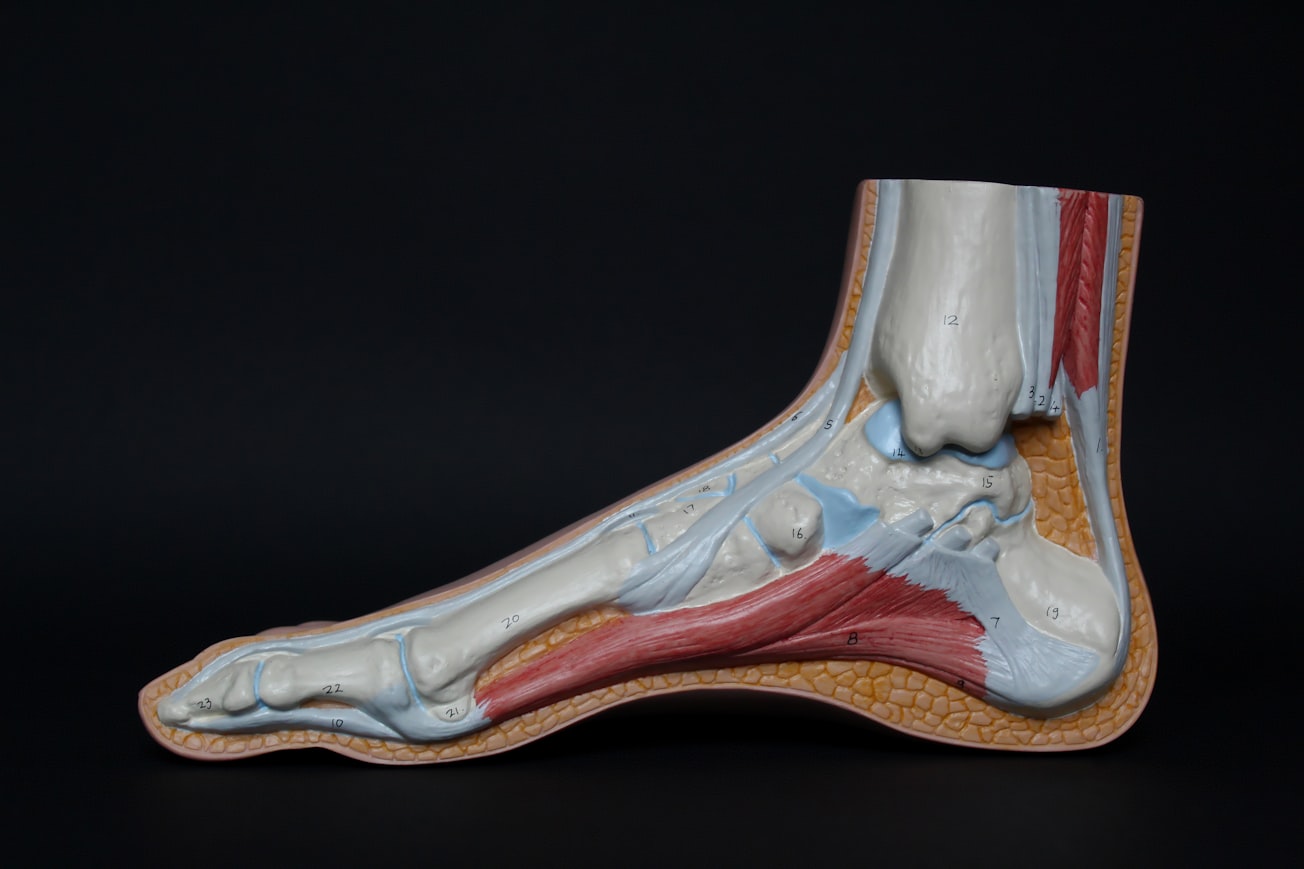

Featured Image

Photo by Anne Nygård on Unsplash

Why is it important?

In this study, the effect of different tool geometry, tool material, different cutting conditions and parameters on the cutting temperature was investigated experimentally. All factors that may cause necrosis during the drilling process were tried to be determined.

Perspectives

Deeper knowledge in the field of bone drilling.

Dr. Ekrem Oezkaya

Recep Tayyip Erdogan Universitesi

Read the Original

This page is a summary of: Kemik Delme İşlemlerinde Farklı Kesme Koşullarının ve Kesme Parametrelerinin Kesme Sıcaklığı Üzerindeki Etkisinin Araştırılması, Journal of Polytechnic, November 2020, Gazi University - Technical Education Faculty,

DOI: 10.2339/politeknik.734894.

You can read the full text:

Resources

Contributors

The following have contributed to this page