What is it about?

it is about enhancing the cupric oxide nanostructures anodized copper coating was successfully synthesized through the electrochemical anodization method. effects of oxalate concentration and temperature on the morphology and corrosion resistance of the anodized coating were investigated through the observation of the critical polarization current variations. The anodizing parameters were selected in the ranges of anodizing temperature 0 - 24 ºC, oxalate concentration 0.1 - 0.5 M, and applied voltage 7.5-9 v. c oxide properties and controlling the coating parameters.

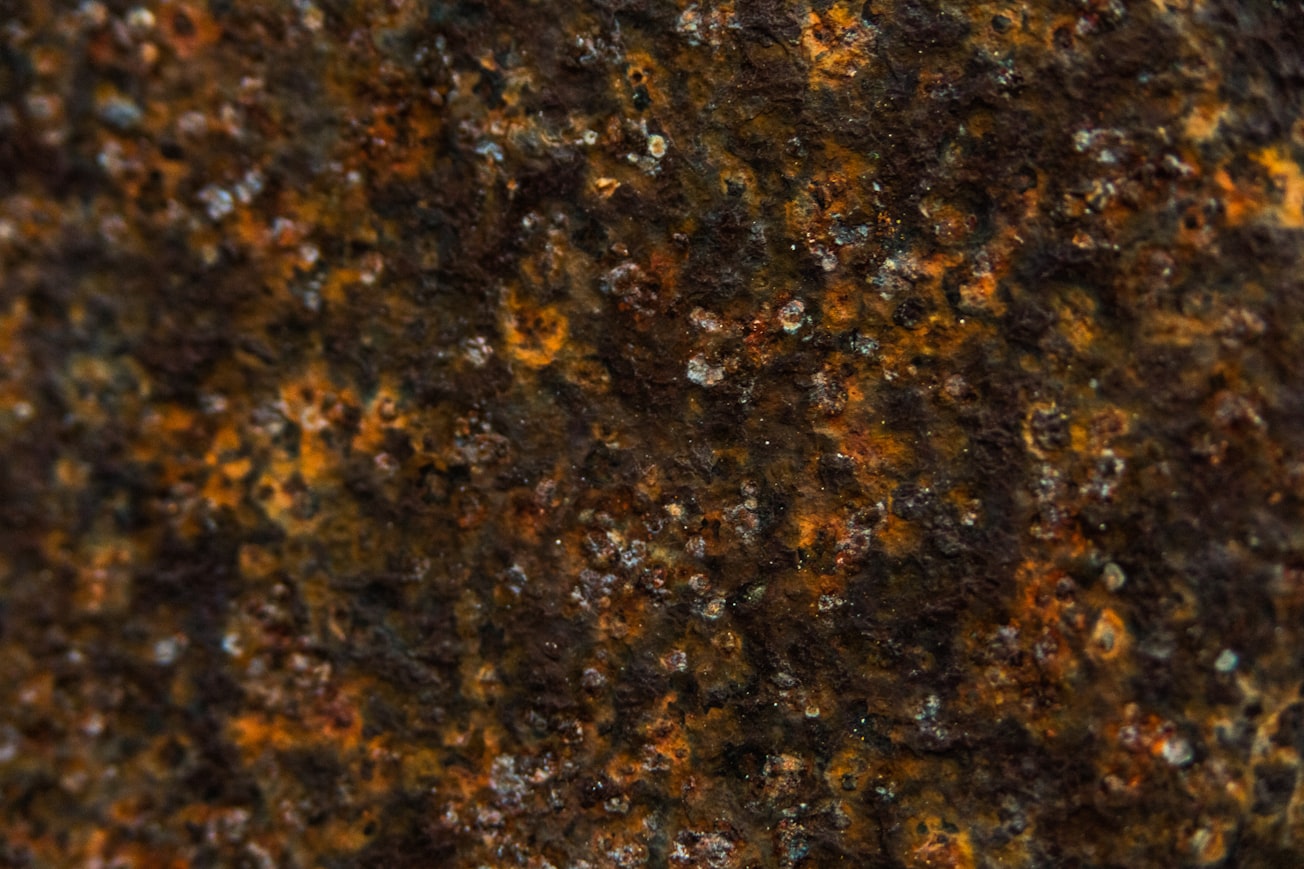

Featured Image

Photo by Patrick Hendry on Unsplash

Why is it important?

high-temperature superconductors, magnetoresistance materials, and memory devices. The highest resistance to charge transfer through the anodized coated surface was achieved in the highest oxalate concentration and lowest anodizing temperature. enhancing the properties of cupric oxide will be contributed to the development of many scientific applications.

Perspectives

The development of copper oxide coating recently was demanded in many fields of scientific applications like gas detection sensors, hydrophobic surfaces, solar cells, and energy storage.

Dr. Mahmood Hameed Mahmood

International Islamic University Malaysia

Read the Original

This page is a summary of: Influence of Oxalate Concentration and Temperature on the Microstructure Morphology of Nano Anodized Copper Coating, Journal of Materials Science and Engineering A, August 2018, David Publishing Company,

DOI: 10.17265/2161-6213/2018.7-8.004.

You can read the full text:

Contributors

The following have contributed to this page