What is it about?

The aim of this article is to study the influence of a Ti6Al4V microstructure on cutting forces during the micromilling process. Samples were annealed above the β-transus at three different temperatures-1020, 1050, 1080°C-and then cooled in a furnace, air, and water, in order to produce different Widmastätten microstructures. Micromilling tests were carried out on heat-treated samples, and the cutting forces were measured by means of a load cell. The results were correlated to the sample microstructures, which were thoroughly investigated by means of an optical microscope, X-ray diffraction, and microhardness measurements. The highest cutting forces were observed for soft and ductile furnace-cooled samples, suggesting that the most important factor affecting workability is the material ductility, while hardness is a less relevant parameter.

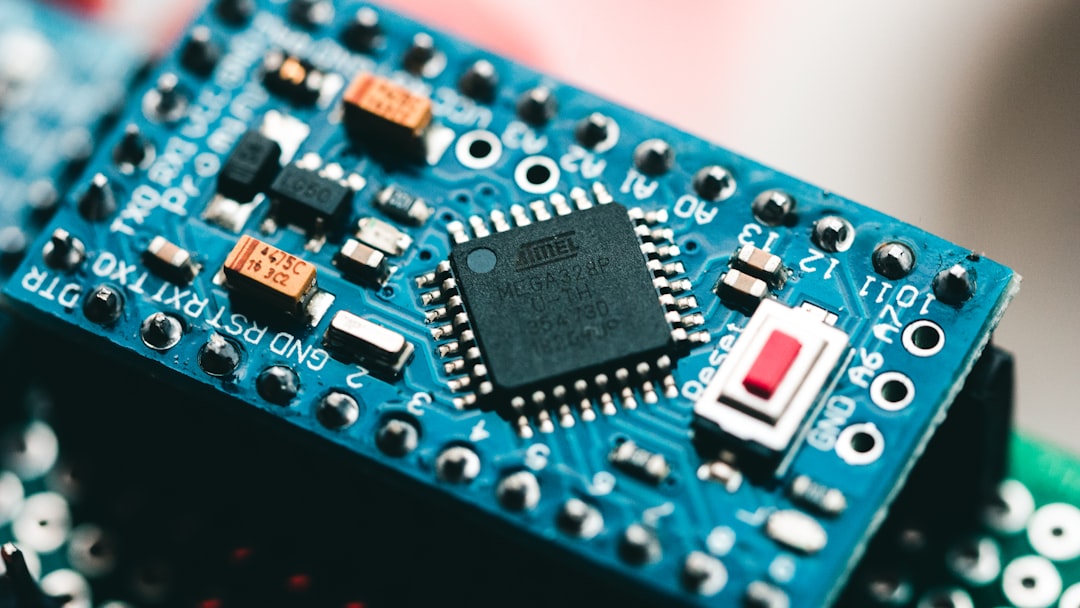

Featured Image

Read the Original

This page is a summary of: Micromilling of Lamellar Ti6Al4V: Cutting Force Analysis, Materials and Manufacturing Processes, June 2015, Taylor & Francis,

DOI: 10.1080/10426914.2015.1059447.

You can read the full text:

Contributors

The following have contributed to this page