What is it about?

Thermally modified (TM) wood production has significantly increased in the last decade. The trend for TM wood residues should be similar – rapidly increasing, which has prompted this research on the possible efficient uses of these residues, such as sawdust. One of the possibilities could be the production of wood plastic composites (WPCs). In this work, three different hydrothermal modification regimes were used to modify birch boards. Modified and unmodified birch boards were milled to obtain sawdust. WPCs were made with a two-roll mill, and they consisted of 50 wt-% wood fibres + 50 wt-% polypropylene. Melt flow index (MFI), flexural properties, impact strength, microhardness water absorption and dimensional stability were tested. WPCs with TM wood showed improvement in flexural properties, MFI and other properties, however there was a decrease in impact strength. Scanning electron microscopy pictures of impact strength samples fracture surfaces were taken.

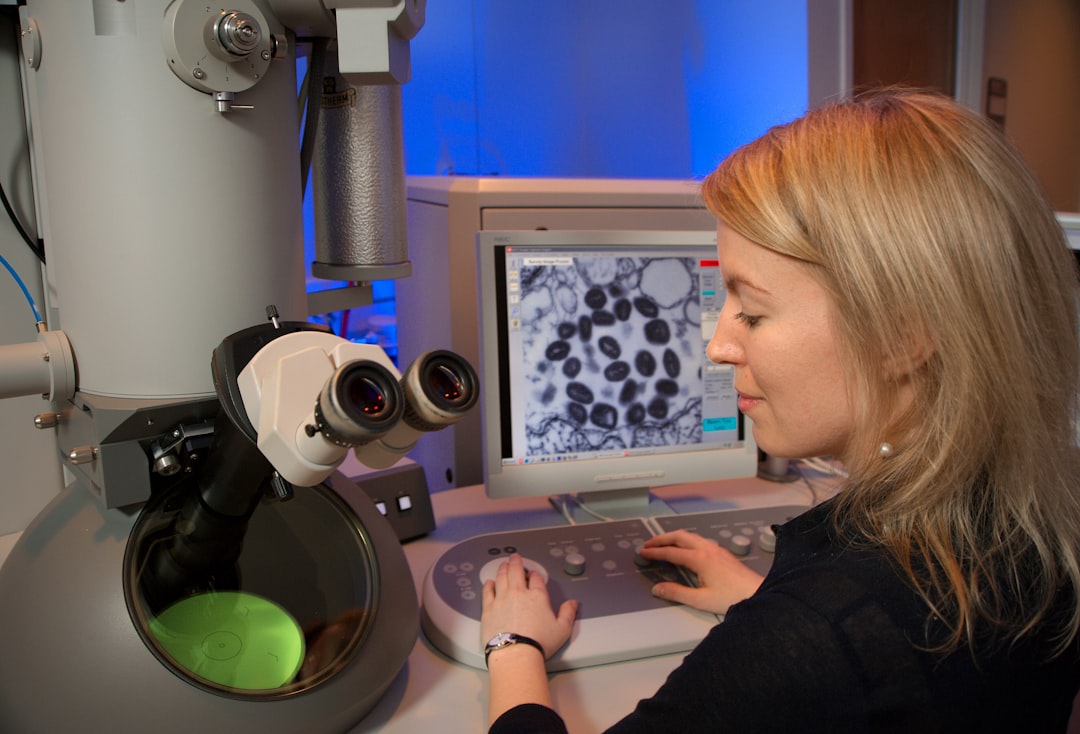

Featured Image

Photo by David Rangel on Unsplash

Why is it important?

The paper shows the benefits of using thermally modified wood instead of unmodified wood for production of wood plastic composites. Increase in water resistance, microhardness, flexural properties are some of the improved properties reported in the paper. Only impact strength was significantly reduced for wood plastic composites made with case of thermally modified wood. Wood modification temperature also is evaluated: regarding the effect on wood plastic composite properties.

Perspectives

The paper evaluates the most important mechanical and physical properties of wood plastic composites and most importantly investigates how addition of thermally modified wood affects them.

Edgars Kuka

Latvian State Institute of Wood Chemistry

Read the Original

This page is a summary of: Wood plastic composites made with thermally modified birch wood residues, International Wood Products Journal, October 2016, Taylor & Francis,

DOI: 10.1080/20426445.2016.1214439.

You can read the full text:

Contributors

The following have contributed to this page