What is it about?

Bore holes with a large length to diameter ratio of up to l/d=100 are typically produced using the single-tube deep hole drilling method also named BTA (Boring and Trepanning Association) deep hole drilling method. However, there are various technical applications requiring deep, complex, epitrochoid-similar and helical inner contours, such as stators used in Moineau motors and pumps. According to the current state of the art, epitrochoid-similar contours for small diameters with large drilling depths can only be produced using a special machining process which is referred to a chamber-boring process. In this paper, a developed mathematical model will be presented that describes the epitrochoidsimilar contour exactly. This allows the determination of the position-dependent speed and acceleration of the tool, which are necessary for designing the joints and components of the tool system. In addition, this mathematical model can be used for a subsequent Laplace-transformation, so that could be used for a further optimization of the process dynamic in the future.

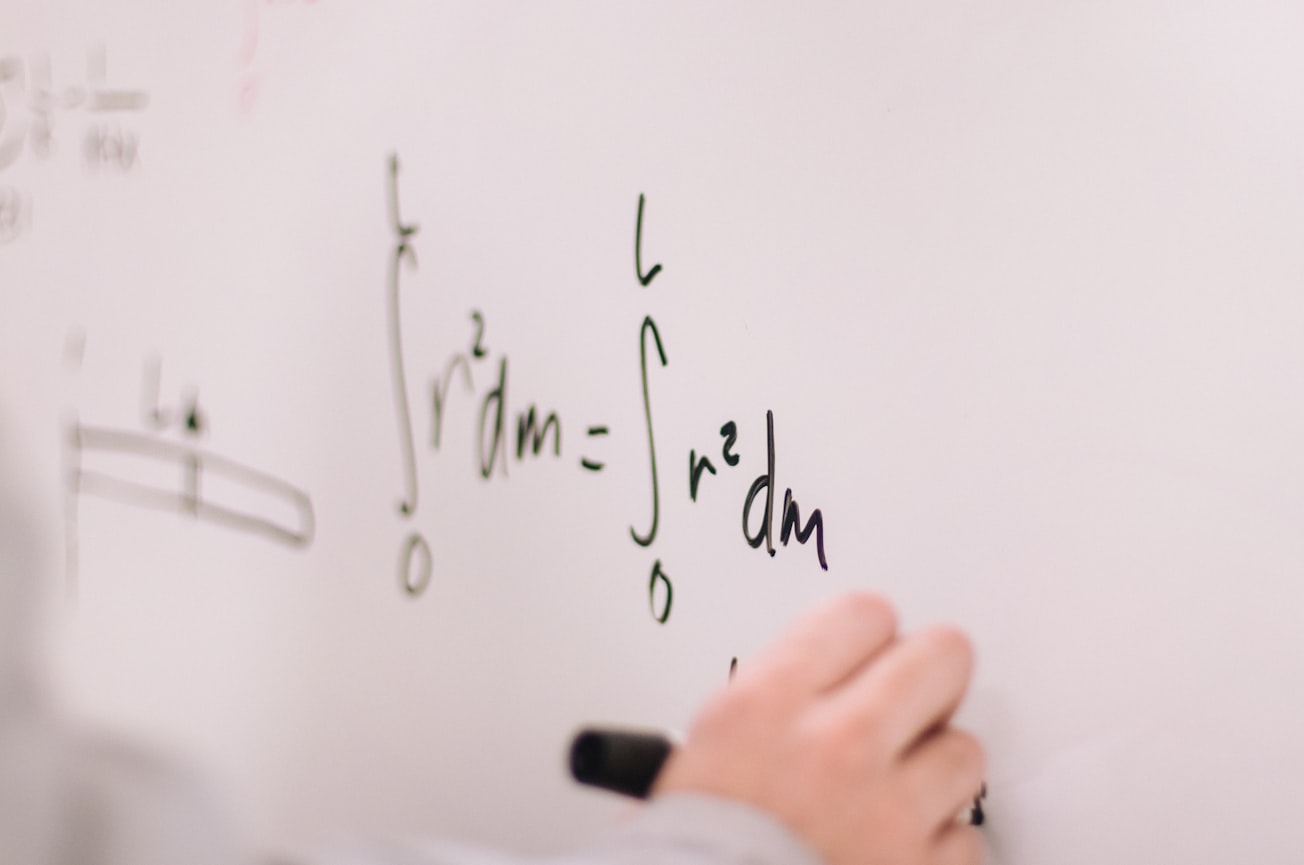

Featured Image

Photo by Jeswin Thomas on Unsplash

Why is it important?

Based on the mathematical model presented here, the kinematic tool movement of the special deep turning process will be optimized with control and regulation technology and the purely mechanical drive will be replaced, so that the epitrochoid-similar profile bores can be manufactured with the required precision.

Perspectives

The developet mathematical model was developed support to improve and develop a new chamber boring process.

Dr. Ekrem Oezkaya

Recep Tayyip Erdogan Universitesi

Read the Original

This page is a summary of: Investigation of coolant distribution of bottle boring systems with computational fluid dynamics simulation, CIRP Journal of Manufacturing Science and Technology, November 2021, Elsevier,

DOI: 10.1016/j.cirpj.2021.05.012.

You can read the full text:

Contributors

The following have contributed to this page