What is it about?

Based on the results of this study, manufacturers of filled chocolate products may adapt their processing parameters such as temperature and retention time in the cooling tunnel accordingly. The analytical methods may be used to control the production of confectionery and to determine filling fat concentrations in the chocolate shells of freshly produced pralines. As different filling lipids in small contents cause similar softening of chocolate shells, the solid fat content (SFC) of chocolate is an appropriate method to control filling lipid migration into chocolate.

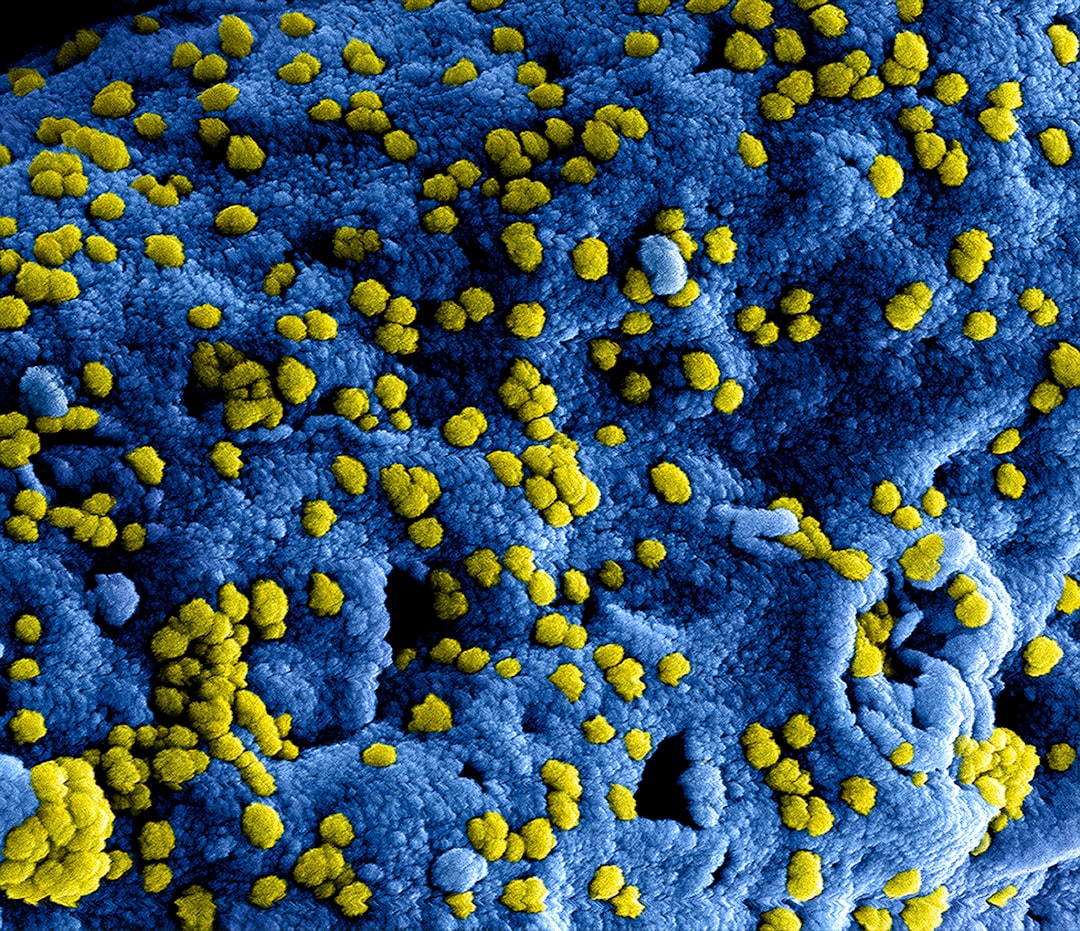

Featured Image

Why is it important?

In this manuscript we describe how different filling lipids, which can migrate during production of chocolate products, influence chocolate crystallization. A lot of research is done on cocoa butter crystallization, while chocolate crystallization is neglected. In addition to established TD-NMR measurements we investigated the samples using the MultiTherm™ (Bühler, Uzwil, Swiss). Our findings can be applied in the chocolate manufacturing process to adjust cooling tunnel settings and to quantify filling lipids in the used chocolate. This study is timely because filling lipid entrainment and improper cooling are suspected to induce fat bloom, which causes high economic loss.

Read the Original

This page is a summary of: Changes in chocolate crystallization are influenced by type and amount of introduced filling lipids, European Journal of Lipid Science and Technology, October 2015, Wiley,

DOI: 10.1002/ejlt.201400552.

You can read the full text:

Contributors

The following have contributed to this page