What is it about?

Additive manufacturing is a revolutionary method for the fabrication of titanium and its alloy compared to traditional technology. The main advantages of additive manufacturing of titanium are 1. Higher so-called buy-to-fly ratio or yield ratio of the material. 2. Lower cost of titanium product as a whole. 3. The ability to produce details of complex dimensional configuration with holes or internal voids. 4. The ability to produce titanium matrix composite with different types of structure and chemical composition; 5. Higher design speed and flexibile production. 6. Green technology. 7. Short lead times. However, in order to use additively manufactured titanium in production, it is necessary to evaluate its corrosion resistance in solutions of inorganic acids.

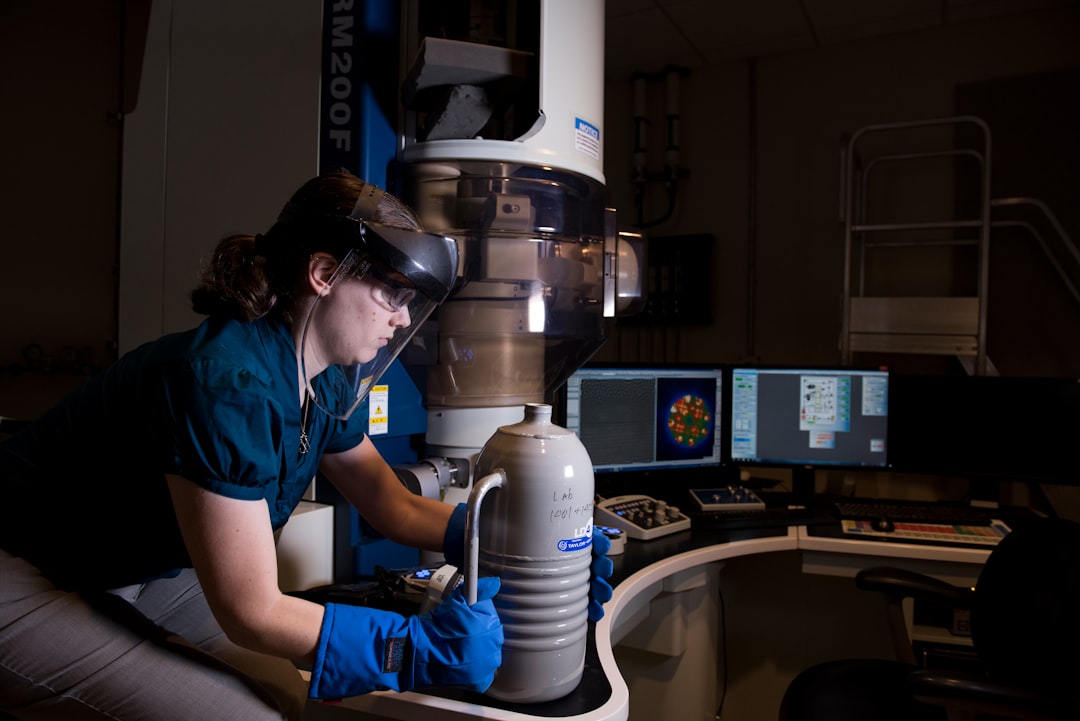

Featured Image

Photo by Clayton Cardinalli on Unsplash

Why is it important?

These studies will be useful for specialists in the chemical, metallurgical, oil and energy industries, where titanium products are used in contact with aggressive media.

Perspectives

Writing this article was a great pleasure as it has co-authors with whom I have had long standing collaborations. This article also lead to ucooperate with entrepreneurs who manufacture titanium products or operate them in production.

Serhii Lavrys

Karpenko Physico-Mechanical Institute of the NAS of Ukraine

Read the Original

This page is a summary of: Corrosion behavior of near‐alpha titanium alloy fabricated by additive manufacturing, Werkstoffe und Korrosion, July 2022, Wiley,

DOI: 10.1002/maco.202213105.

You can read the full text:

Contributors

The following have contributed to this page