What is it about?

3D printing allows complex objects to be made, some finishing steps are normally required, one thing which is commonly done is to create screw threads for making connections. We showed that screw threads can be 3D printed and they are just as strong as normal threads.

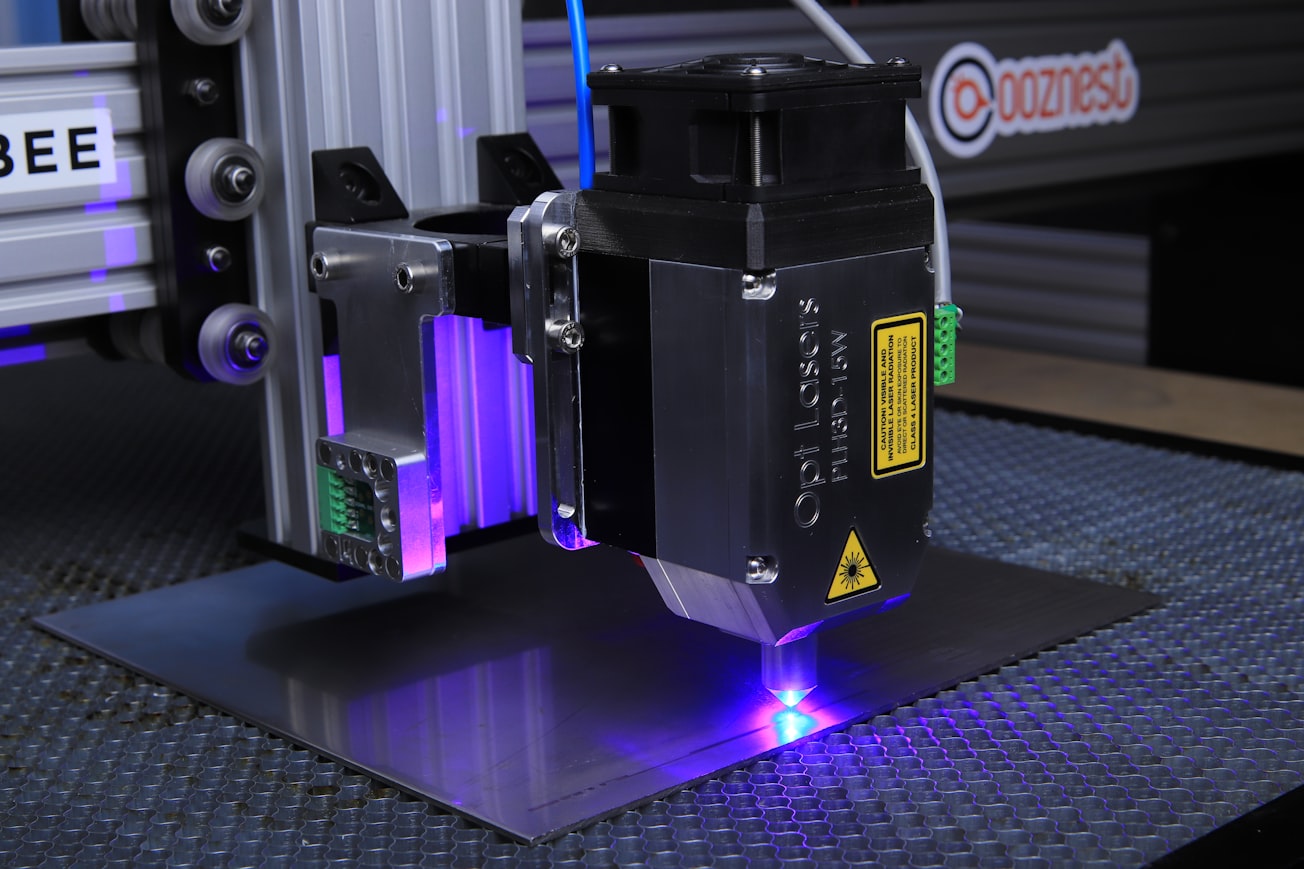

Featured Image

Photo by Opt Lasers on Unsplash

Why is it important?

Being able to complete more of an object by 3D printing reduces time spent on finishing objects, and by printing 3D threads these are potentially much more accurately aligned to the original design. In our example we focussed on plates used to fix bone fractures, these are usually held in place by locking screws. If the locking screws are not aligned correctly they represent a potential weak point.

Perspectives

Being able to 3D print custom fracture fixation plates, complete with threads, will enable personalised treatment. Reducing the overall number of manufacturing steps reduces cost and simplifies the process of making complex objects. We are using these plates to enable personalised high tibial osteotomy, with personalised surgical guides to accurately perform the surgery. Having plates with well aligned screw threads will contribute to the overall surgical accuracy.

Richie Gill

University of Bath

Read the Original

This page is a summary of: 3D printed locking osteosynthesis screw threads have comparable strength to machined or hand‐tapped screw threads, Journal of Orthopaedic Research®, May 2020, Wiley,

DOI: 10.1002/jor.24712.

You can read the full text:

Contributors

The following have contributed to this page