What is it about?

When two different metals in contact are connected by a solution, which can be in the form of a light rain or morning dew,, a severe form of corrosion can occur. The water solution acts as a pathway for the ions to flow, allowing one of the metals to corrode severely while the other metal remains protected. In this study, stainless steel bolts and an aluminum alloy panel were the focus of the dissimilar metals. The study was conducted through modeling techniques, so that the distribution of corrosion could be seen.

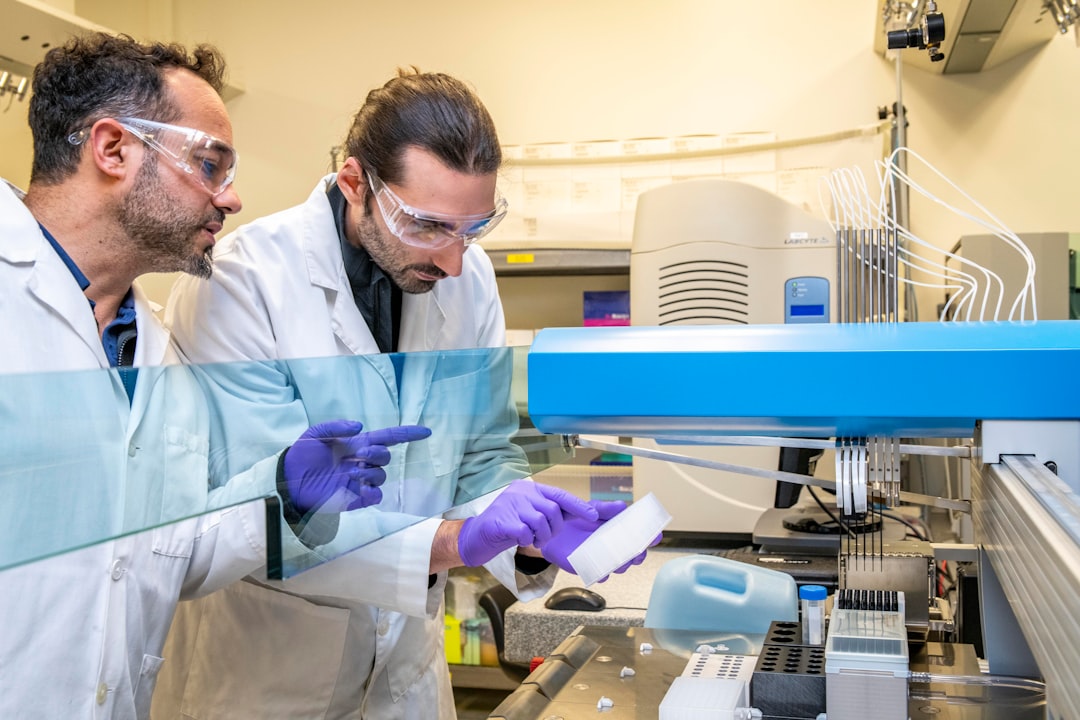

Featured Image

Photo by Patrick Hendry on Unsplash

Why is it important?

In this work, it was determined that the stainless steel bolt and washer could severely corrode the aluminum alloy panel up to two inches away! Because the aluminum alloy panel represented the siding of an aircraft, this result showed that maintenance and inspection should be done over a larger region of the aircraft, rather than just in the vicinity of the bolts. Understanding how far the bolt can corrode the aluminum is also important for preventing corrosion. When a coating was applied to the fastener, the distance of corrosion on the panel was decreased tremendously. It was determined that coating the washer was more important than coating the bolt, in our specific case, because the washer had the largest surface area compared to the bolt.

Read the Original

This page is a summary of: Estimating the Throwing Power of SS316 When Coupled with AA7075 Through Finite Element Modeling, CORROSION, March 2020, NACE International,

DOI: 10.5006/3438.

You can read the full text:

Contributors

The following have contributed to this page