What is it about?

The article compares the process of manufacture of U clamps using a transfer die and a combination die and concludes that the cost of manufacture is lesser with a combination die as the number of steps to manufacture and hence the labour involved is reduced.

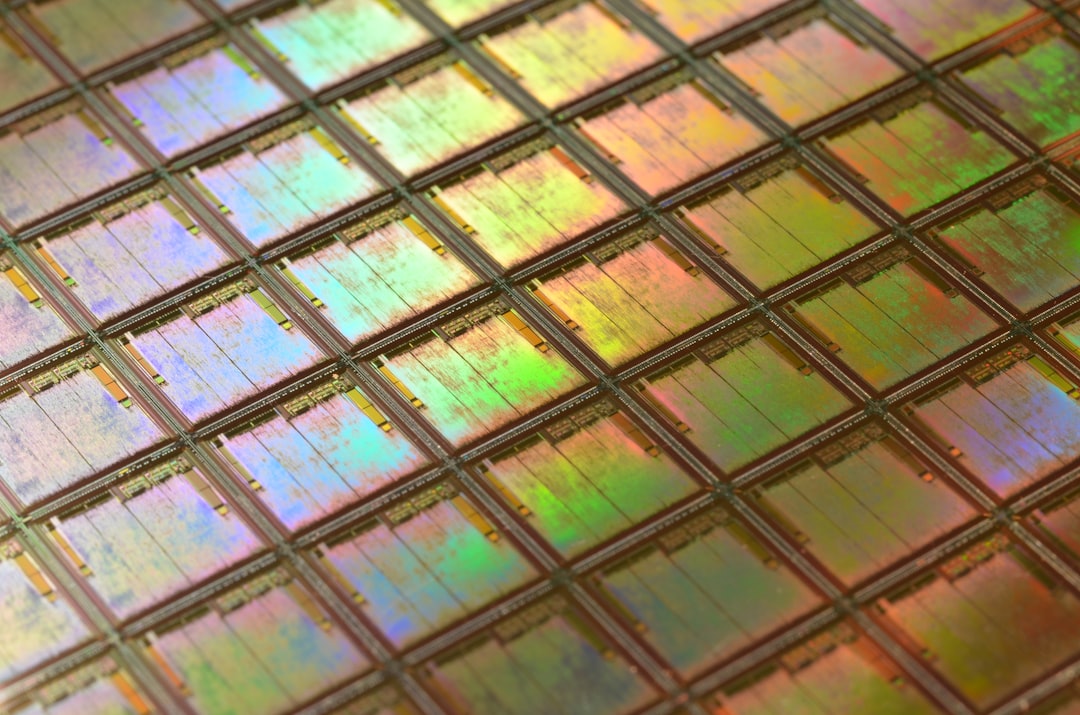

Featured Image

Why is it important?

It shows a real world example where advancement in tool and die design could directly contribute to the profitability of sheet metal business. The paper shows how the punching, bending and trimming operations are combined into one step in a combination die, which would otherwise require two or three stages in a transfer die.

Perspectives

The article explains the various steps in making U clamp from sheet metal and points to good reference material for die design. in addition the cost analysis shows the real worthiness after making the right choice of machine and materials.

Dr Deivanathan R

VIT University

Read the Original

This page is a summary of: Reducing the Manufacturing Cost by Using Combination Die, Applied Mechanics and Materials, November 2012, Trans Tech Publications,

DOI: 10.4028/www.scientific.net/amm.234.59.

You can read the full text:

Contributors

The following have contributed to this page