What is it about?

Cold spray is emerging as an additive manufacturing technique, particularly advantageous when high production rate and large build sizes are in demand. To further accelerate technology’s industrial maturity, the problem of geometric control must be improved, and a neural network model has emerged to predict additively manufactured geometry. However, limited data on the effect of deposition conditions on geometry growth is often problematic. Therefore, this study presents data-efficient neural network modelling of a single-track profile in cold spray additive manufacturing. Two modelling techniques harnessing prior knowledge or existing model were proposed, and both were found to be effective in achieving the data-efficient development of a neural network model. We also showed that the proposed data-efficient neural network model provided better predictive performance than the previously proposed Gaussian function model and purely data-driven neural network. The results indicate that a neural network model can outperform a widely used mathematical model with data-efficient modelling techniques and be better suited to improving geometric control in cold spray additive manufacturing.

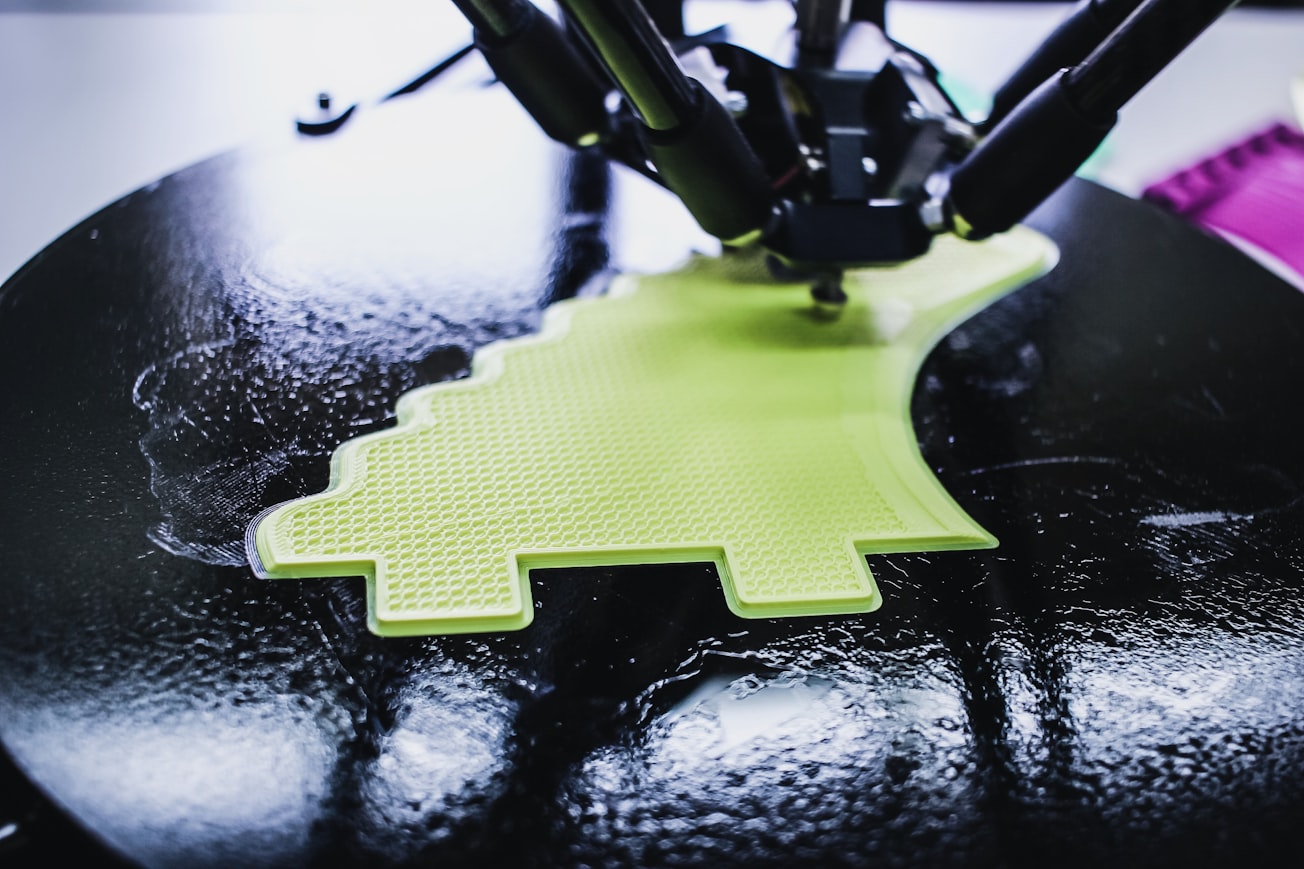

Featured Image

Photo by Ines Álvarez Fdez on Unsplash

Why is it important?

Poor geometric control places many limitations on applying HPRAM technologies; examples include varying geometric quality, difficulty producing complex geometries, and geometry-induced property variations. Hence, geometric control must be addressed to facilitate further development and commercial integration of CSAM and other HPRAM technologies.

Perspectives

The significance of this study is four-fold: (1) the application of a data-driven modelling approach with a data-efficient focus in the prediction of a single-track profile in CSAM; (2) the comparative study among purely mathematical function, purely data-driven and data-efficient data-driven modelling approaches, in the context of HPRAM; (3) the demonstration that data-driven modelling can outperform more widely used mathematical modelling with appropriate data-efficient techniques in HPRAM; and (4) that existing models at hand can contribute to the development of a new data-driven model with better prediction accuracy without further experimentation.

Mr Daiki Ikeuchi

University of Cambridge

Read the Original

This page is a summary of: Data-Efficient Neural Network for Track Profile Modelling in Cold Spray Additive Manufacturing, Applied Sciences, February 2021, MDPI AG,

DOI: 10.3390/app11041654.

You can read the full text:

Resources

Data-Efficient Neural Network for Track Profile Modelling in Cold Spray Additive Manufacturing

Open access full article

Hybrid Predictive Modelling of Geometry with Limited Data in Cold Spray Additive Manufacturing

Presentation

Supplementary materials for "Data-Efficient Neural Network for Track Profile Modelling in Cold Spray Additive Manufacturing"

Supplementary materials including data

Neural Network Modelling of Track Profile in Cold Spray Additive Manufacturing

Our related open access full article

Machine Learning Approach to Geometry Prediction in Cold Spray Additive Manufacturing

Poster presentation of our related work

Contributors

The following have contributed to this page