What is it about?

Phosphoric acid (PA) is an important industrial chemical used as an intermediate in the fertilizer industry, for metal surface treatment in the metallurgical industry, and as an additive in the food industry. Wet-process PA (WPA) is produced by the attack of sulfuric acid (H2SO4) on phosphate rock (PR). Other wet processes use HCl and posterior solvent extraction technology. The corrosivity of phosphate ores, during the production of WPA, depends on two main factors: the chloride content and the interaction between HF formed in the WPA reaction slurry with SiO2, Al2O3, and MgO present in the ore. Many forms of corrosion, mainly localized, are encountered in the PA production plants and facilities such as erosion-corrosion (EC), selective corrosion, pitting, stress-corrosion cracking, intergranular corrosion, and corrosion at high temperature. Laboratory and plant corrosion tests were performed to recognize the corrosion types; EC measuring instruments were developed, built, and applied. The PA industry is spread out worldwide in Europe, Asia, Africa and America, including countries that operate PR mines and produces PA, phosphatic fertilizers, and phosphatebased products. Cases of corrosion in PA industrial equipment and plants are presented and discussed, based on the authors’ experience and knowledge.

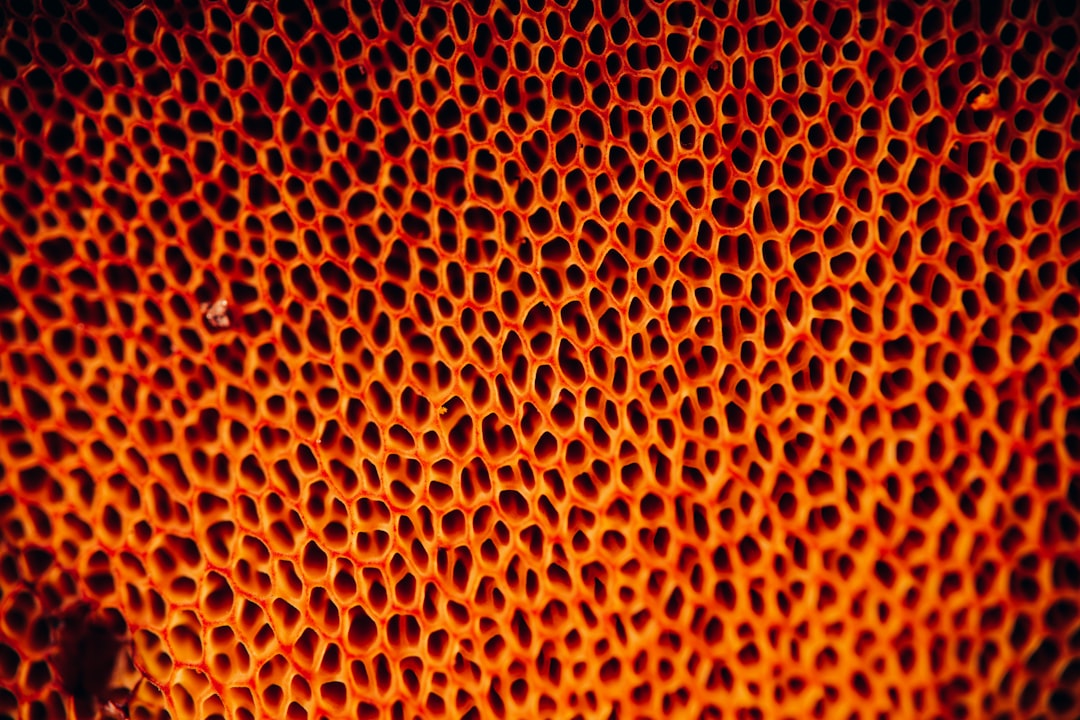

Featured Image

Read the Original

This page is a summary of: The phosphoric acid industry: equipment, materials, and corrosion, Corrosion Reviews, January 2016, De Gruyter,

DOI: 10.1515/corrrev-2015-0061.

You can read the full text:

Contributors

The following have contributed to this page