What is it about?

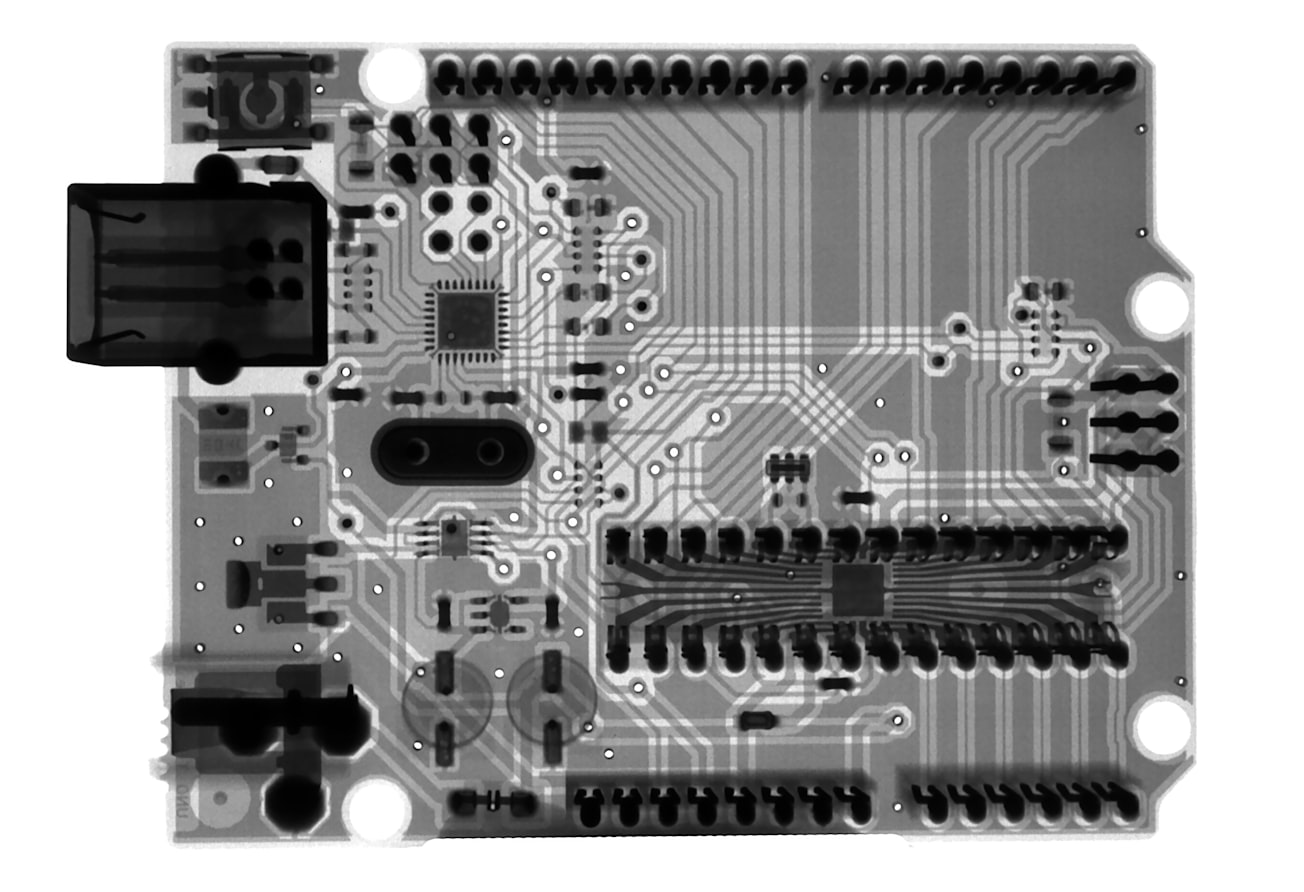

Detection of cracks, closed channels and chips in water cooling case of cast component using R-CNN.

Featured Image

Photo by Mathew Schwartz on Unsplash

Why is it important?

The availability of real components with defects that can be used to train a CNN is often limited, so that the generation of a synthetic database is necessary. In this paper an approach and its results are presented.

Perspectives

The use of AI, especially Deep Learning, for industrial CT image analysis is still at the verge of becoming a standard approach. The potential to fully automate nowadays manual inspection tasks, e.g. crackt detection, anomaly detection or segmentation, is immense. In interaction with fast scanners the implementation of Deep Learning in the analysis process can significantly reduce the inspection costs and time. Thus, CT inspection becomes less expensive (cost per parts) and an economical inspection method for parts also with lower unit prices, leading to a growth of the market for CT inspection services.

Robin Höhne

Read the Original

This page is a summary of: Einsatz von Methoden des maschinellen Lernens in der CT-Messtechnik, tm - Technisches Messen, November 2019, De Gruyter,

DOI: 10.1515/teme-2019-0075.

You can read the full text:

Contributors

The following have contributed to this page