What is it about?

Multi-axis motion introduces more degrees of freedom into the process of 3D printing to enable different objectives of fabrication by accumulating materials layers upon curved layers. This paper presents a general slicing framework for achieving multiple fabrication objectives including support-free, strength reinforcement, and surface quality.

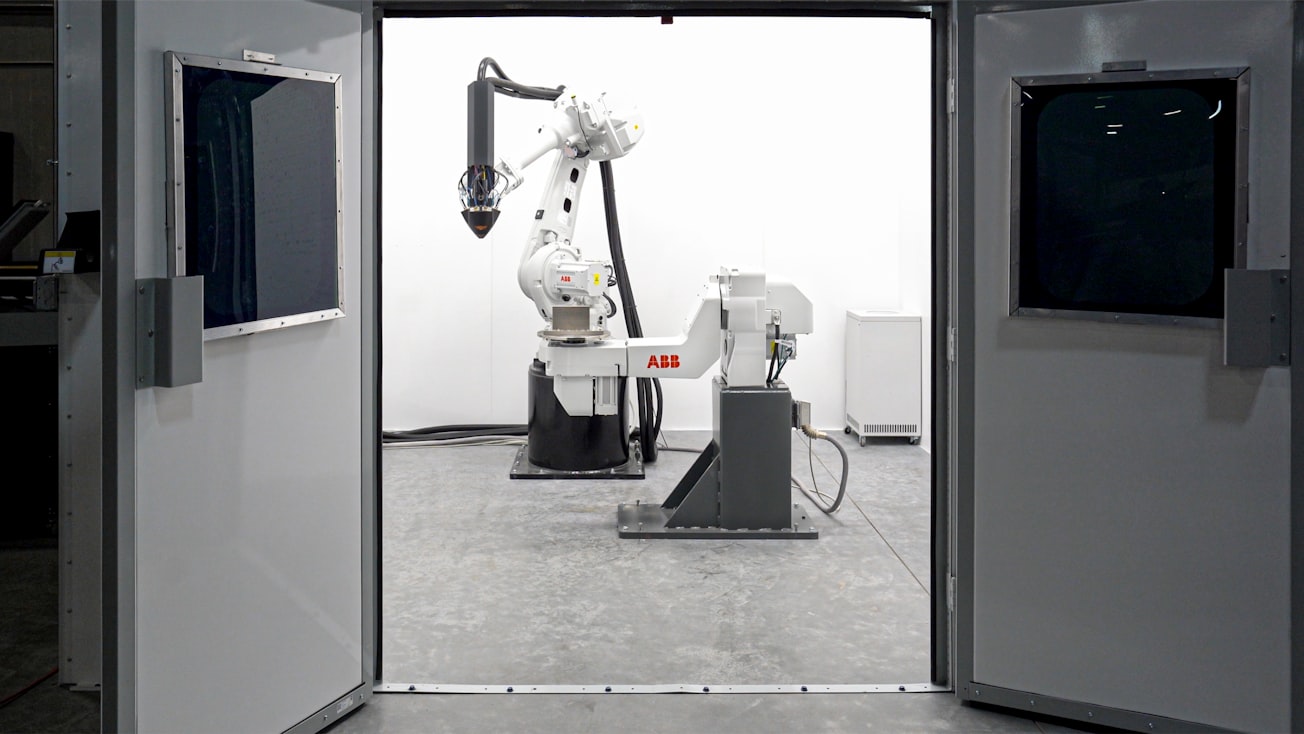

Featured Image

Photo by Hermeus on Unsplash

Why is it important?

An existing challenge is how to effectively generate the curved layers satisfying multiple objectives simultaneously. These objectives are formulated as local printing directions varied in the volume of a solid, which are achieved by computing the rotation-driven deformation for the input model. The deformation can be effectively optimized with the help of quaternion fields to achieve the fabrication objectives. The effectiveness of our method has been verified on a variety of models.

Perspectives

It is my pleasure to collaborate with co-authors from our research group and the professor from INRIA, I hope this work can provide a general solution for the curved 3D printing community. The algorithm can be further extended to specific needs, such as unsupported metal printing, and carbon fibre strength-enhancing printing.

Tianyu Zhang

University of Manchester

Read the Original

This page is a summary of: S

3

-Slicer, ACM Transactions on Graphics, November 2022, ACM (Association for Computing Machinery),

DOI: 10.1145/3550454.3555516.

You can read the full text:

Resources

Contributors

The following have contributed to this page