What is it about?

This paper deals with the investigating the complex mode of heat transfer between nitrogen gas and glass using computational fluid dynamics tool for the precision glass molding process. This mode of heat transfer is modeled suitably in FE simulation to account the heat transfer between glass and nitrogen gas. Residual birefringence (or stress) measured experimentally is inversely used to quantify the suitable values to be used to model the thermal boundary condition.

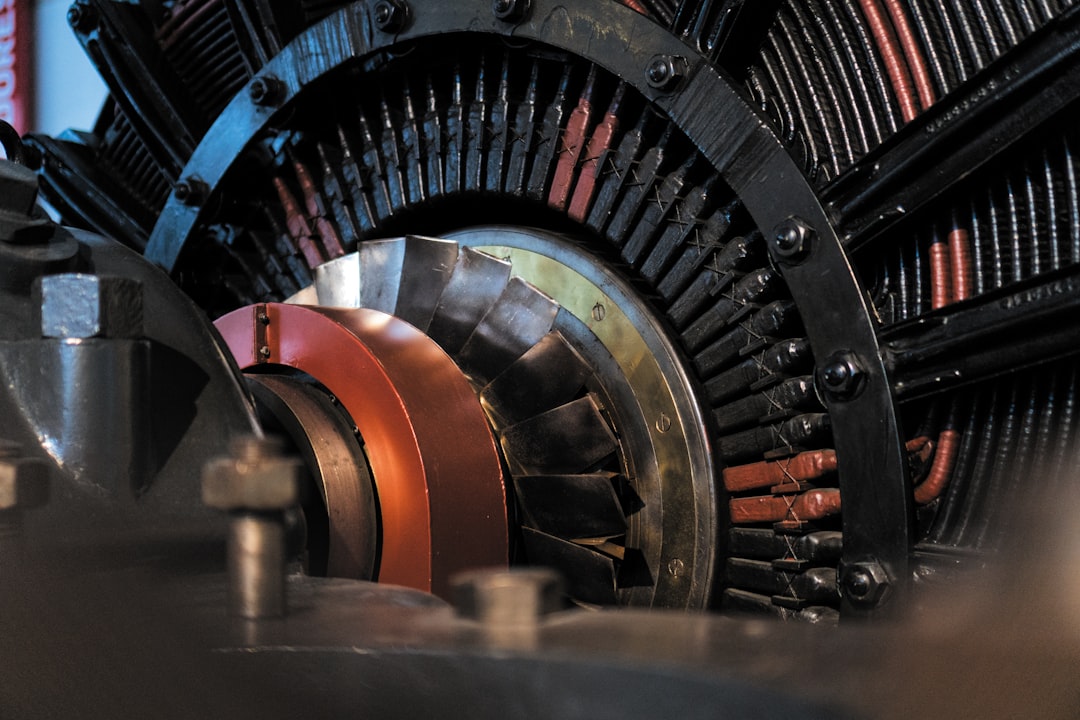

Featured Image

Why is it important?

This research work prescribes a simulation tool for selection of appropriate thermal cycle and other process parameters that would yield minimal residual stress in glass lens. It would help in avoiding performing repetitive trial and error experiments for selection of process parameters. In addition it gives an understanding on modeling the cooling stage of glass molding process and the range of values to be used for the thermal boundary condition on the surface of the glass that interacts with nitrogen gas.

Read the Original

This page is a summary of: Numerical Modeling of Cooling Stage of Glass Molding Process Assisted by CFD and Measurement of Residual Birefringence, Journal of the American Ceramic Society, October 2015, Wiley,

DOI: 10.1111/jace.14000.

You can read the full text:

Contributors

The following have contributed to this page