What is it about?

Selective Inhibition Sintering or SIS is a novel platform 3D Printing technology that is capable of fabricating parts out of polymers, metals and ceramics. In this paper, the development of a high resolution metal 3D printer based on a commercial piezoelectric inkjet technology is explained. It is shown that this machine can produce high resolution metallic parts with a significant reduction in cost compared to other commercial metal 3D printers.

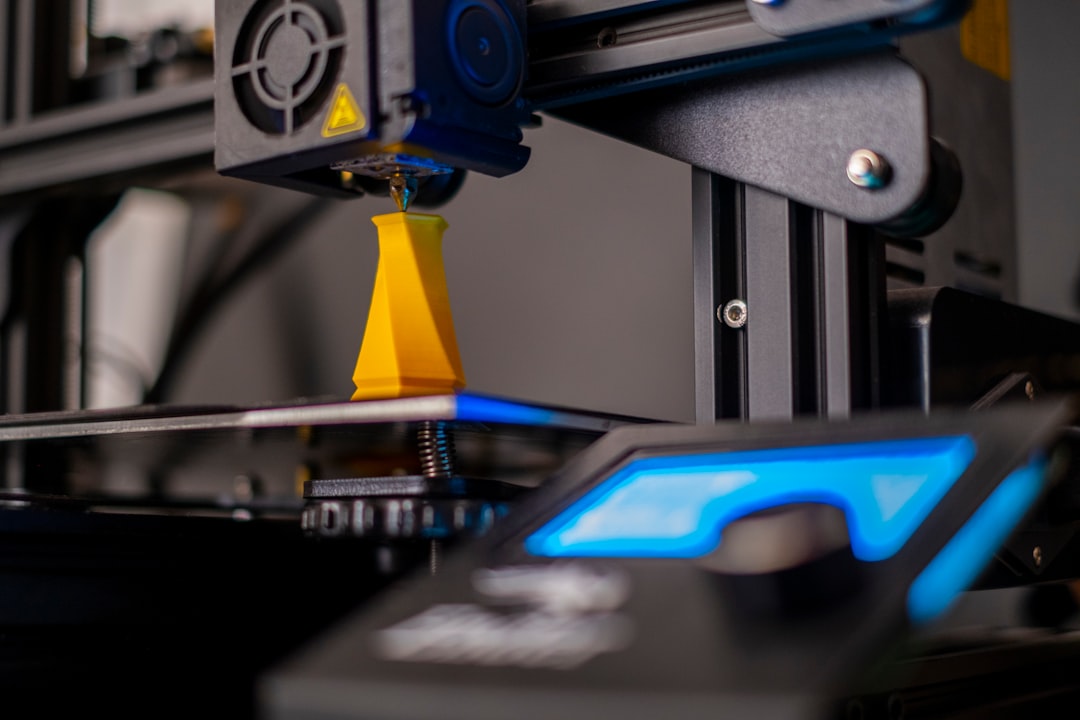

Featured Image

Why is it important?

SIS-metal technology has several advantages over other technologies which are mentioned in the paper. The most important advantage however, is its ability in fabricating high-resolution and high-quality metallic parts with orders of magnitude reduction in cost. With the utilization of SIS in a commercial 3D printer, a larger group of engineers and innovators will benefit from the opportunities that 3D printing has created in the modern world.

Perspectives

3D printing has already made a significant impact on many aspects of people's lives, including, but not limited to education, medicine, industries, and art. With the introduction of consumer plastic 3D printers, the creativity level of the users in different fields of science, art and technology faced a considerable increase. Our team's goal is to develop the first consumer metal 3D printer,based on the SIS technology, to further disrupt an already disrupted industry.

Mr Payman Torabi

University of Southern California

Read the Original

This page is a summary of: Enhancing the resolution of selective inhibition sintering (sis) for metallic part fabrication, Rapid Prototyping Journal, March 2015, Emerald,

DOI: 10.1108/rpj-12-2014-0181.

You can read the full text:

Contributors

The following have contributed to this page