What is it about?

Purpose – The purpose of this paper is to provide a practical review of the use of the minimum quantity lubrication (MQL) system in turning operations, focussing on the application of the technique in the turning of different kind of materials. Design/methodology/approach – The use of the MQL system was analysed by several researchers in the past years. Thus, in the present paper, a relevant sample of the main experimental studies that can be found in the literature was analysed to come up with a review with relevant information for researchers and industry. Findings – The use of the MQL system can help to improve the outcomes of the turning process in several issues like surface quality or tool life. However, it was also recognised that in some cases, other cooling/lubricating methods can provide better results than the MQL system. Thus, the decision, whether to use or not the MQL system in a specific process, is of great importance. Originality/value – The work is conveniently focussed to serve as a quick reference on the issue. At the same time, the work analysed the use of the turning of some of the main engineering materials that makes it useful for a wider range of researchers and metalworking firms. Finally, the review could be useful to improve the performance of the industry, especially for the metalworking firms in terms of costs, environmental impact and safety.

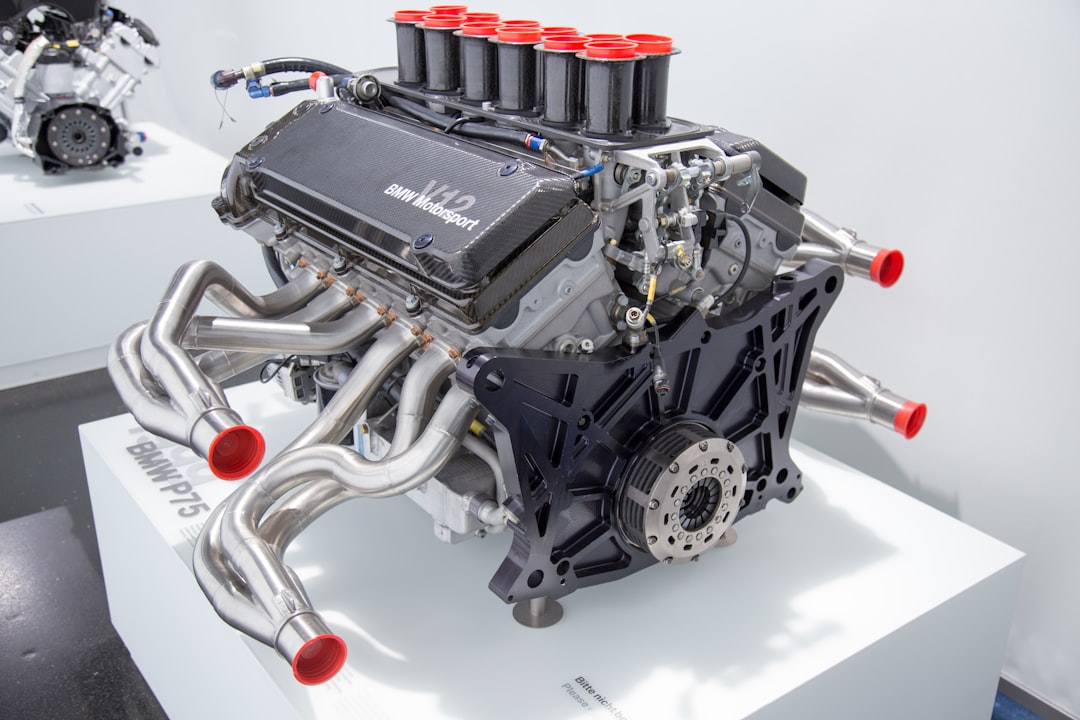

Featured Image

Read the Original

This page is a summary of: A note on the use of the minimum quantity lubrication (MQL) system in turning, Industrial Lubrication and Tribology, April 2015, Emerald,

DOI: 10.1108/ilt-07-2014-0070.

You can read the full text:

Contributors

The following have contributed to this page