What is it about?

This paper describes a knowledge-base system developed for identifying the most appropriate welding processes to suit specific circumstances. In the present study, nine important welding processes were used in the system. Ten parameters namely alloy class, material thickness, deposition rate, design appli-cation, joint configuration, operator factor, capital cost, equipment portability, filler metal utilization and welding position, are used to determine the best selection among competitive welding processes for high pressure vessel production. Also the sensitivity analysis was carried out for five cases.

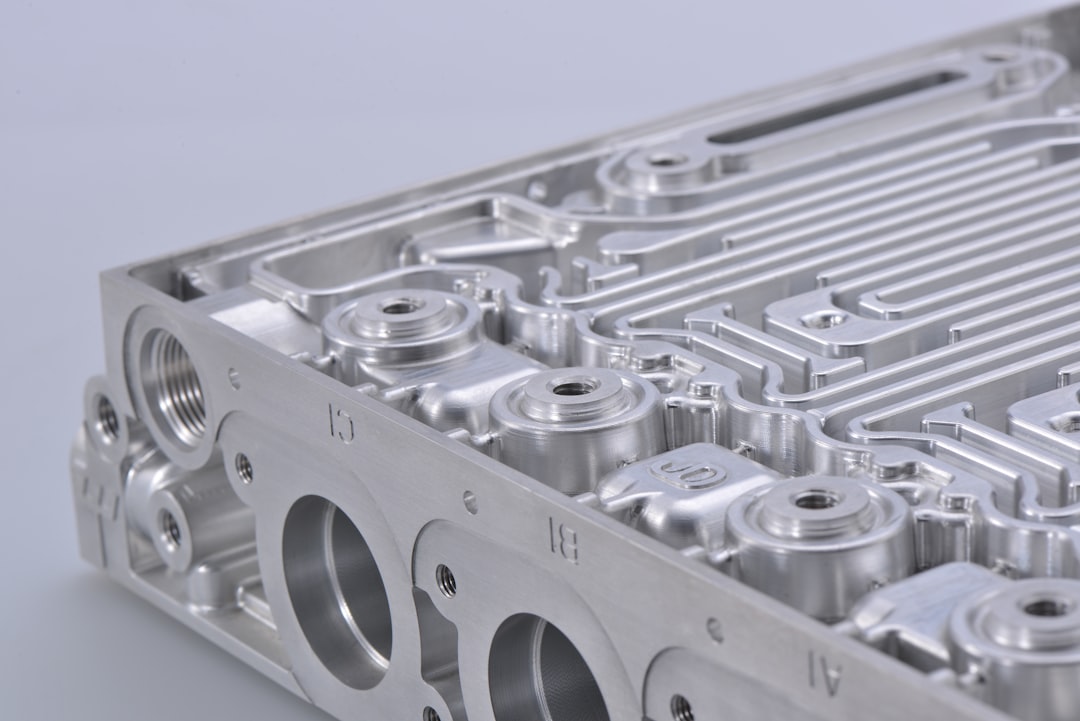

Featured Image

Why is it important?

Metal welding process selection calls for extensive know-how which deals with a huge amount of knowl-edge. Hence, the automation of knowledge through a knowledge-based system will greatly enhance the decision-making process. Fuzzy analytical hierarchy process (AHP)-TOPSIS investigates the relative weld-ing process selection factors and it can compare and evaluate different welding processes between 0 and 1.

Read the Original

This page is a summary of: A fuzzy multi-attribute approach to select the welding process at high pressure vessel manufacturing, Journal of Manufacturing Processes, August 2012, Elsevier,

DOI: 10.1016/j.jmapro.2011.10.006.

You can read the full text:

Contributors

The following have contributed to this page