What is it about?

A low maintenance, “self-cleaning” electrochemical approach is evaluated for regeneration of dye-loaded granular activated carbon (GAC). To do so, batch experiments were conducted using a low-cost granular activated carbon/stainless steel mesh (GACSS) composite cathode and a stable Ti/mixed metal oxides (Ti/MMO) anode without the addition of oxidants or iron catalysts. The GACSS cathode supports simultaneous H2O2 electrogeneration via the in situ supplied O2 from Ti/MMO anode and the subsequent H2O2 activation for OH generation, thus enabling the cracking of dye molecules adsorbed on GAC and regenerating the GAC's sorption capacity. Results show that a prolonged electrochemical processing for 12 h will achieve up to 88.7% regeneration efficiency (RE). While RE decreases with multi-cycle application, up to 52.3% could still be achieved after 10 adsorption-regeneration cycles. To identify the mechanism, experiments were conducted to measure H2O2 electrogeneration, H2O2 activation, and OH generation by various GAC samples. The dye-loaded GAC and GAC treated after 10 adsorption-regeneration cycles were still capable of OH generation, which contributes to effective “self-cleaning” and regeneration over multi-cycles.

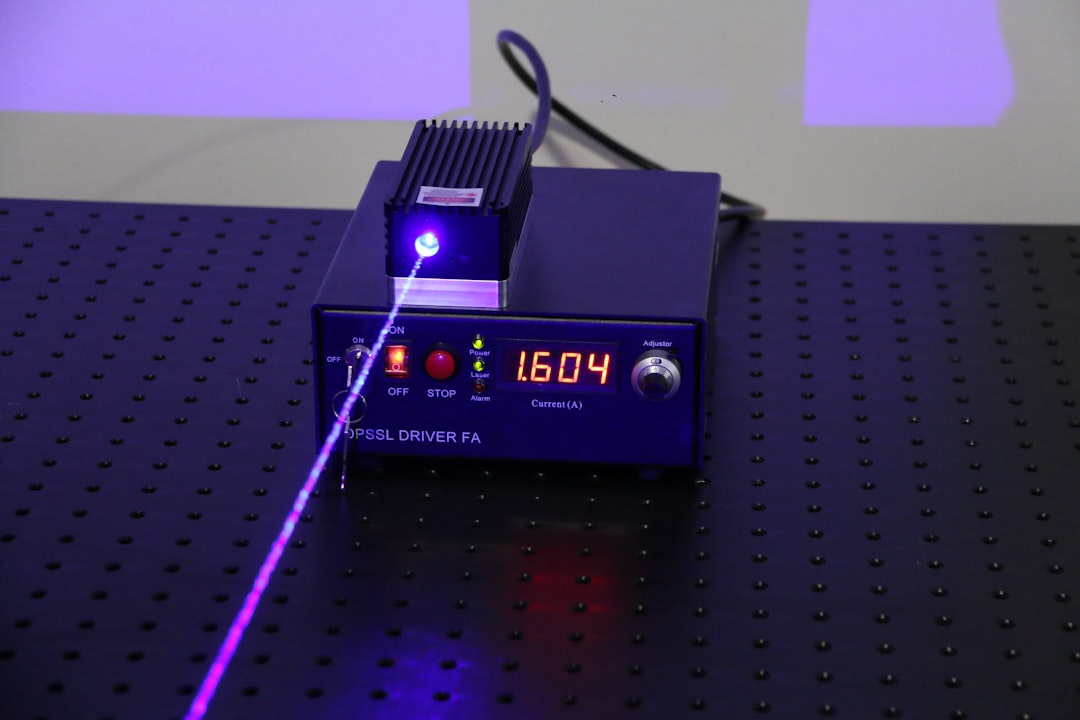

Featured Image

Read the Original

This page is a summary of: “Self-cleaning” electrochemical regeneration of dye-loaded activated carbon, Electrochemistry Communications, February 2019, Elsevier,

DOI: 10.1016/j.elecom.2019.01.025.

You can read the full text:

Contributors

The following have contributed to this page