What is it about?

The aim of the above-mentioned modification is a limitation of the wear zone at the cutting edge and the improvement of cutting fluid supply, especially at the cutting edge corners being subjected to the highest thermal stresses. During the experimental trials the wear progression of the tools as well as the occurring mechanical loads and the influences on the bore hole quality were analysed. The results show that a flank face modification of twist drills has the potential to notably extend the tool life of twist drills that are used to machine Inconel 718.

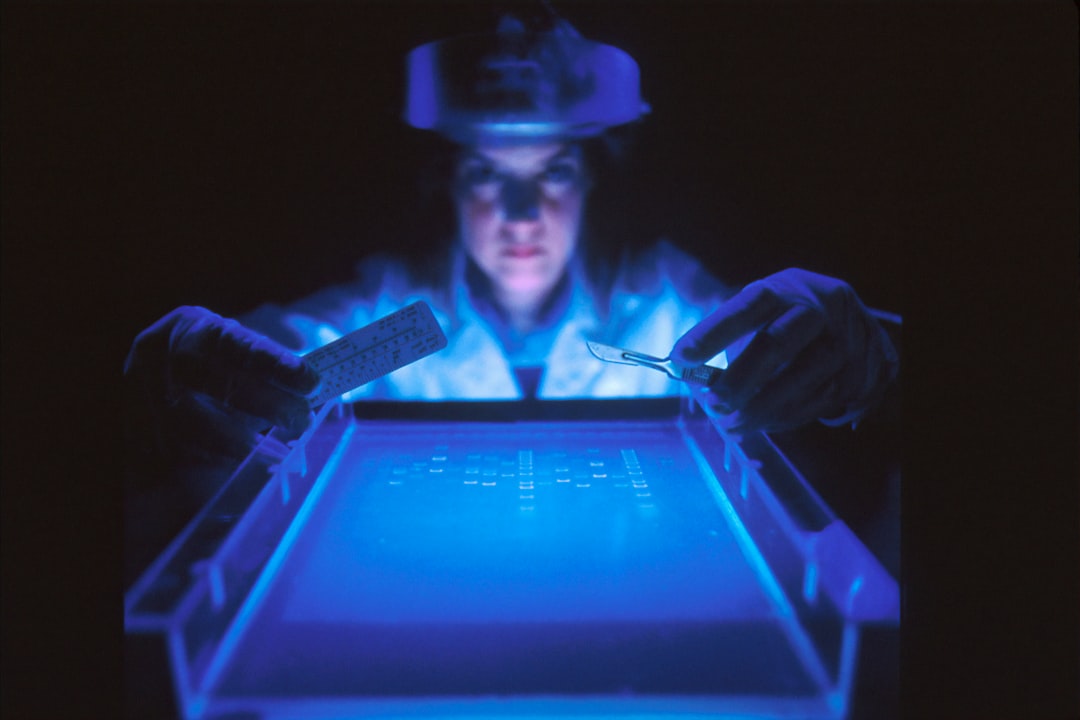

Featured Image

Photo by Riccardo Annandale on Unsplash

Why is it important?

A tool design could be developed that provides important benefits while still being able to withstand the occurring loads

Perspectives

Potential to notably extend the tool life of twist drills that are used to machine Inconel 718.

Dr. Ekrem Oezkaya

Turk-Alman Universitesi

Read the Original

This page is a summary of: Investigations on the effects of an innovative flank face modification for the drilling of nickel-base alloys, Procedia Manufacturing, January 2018, Elsevier,

DOI: 10.1016/j.promfg.2018.11.003.

You can read the full text:

Resources

Contributors

The following have contributed to this page