What is it about?

This work aims to study the morphology of gamma-TiAl alloy and its dependence on the hardness value. It was observed that there was a change in the hardness value when the specimens with the absence and presence of alloying elements were exposed to different heat treatment cycles. The specimen with alloying elements introduced to heat treatment cycle 2 faced an increment in hardness value by 5.28 HV10 with respect to the specimen without alloying elements. This effect became salient because of the agehardening factor that superseded the existence of boron as a grain refiner. The formation of required phases was confirmed by the XRD (X-ray diffraction) test. Correspondingly, the optical microscope and scanning electron microscope tests corroborated the results obtained from the Micro-Vickers hardness test.

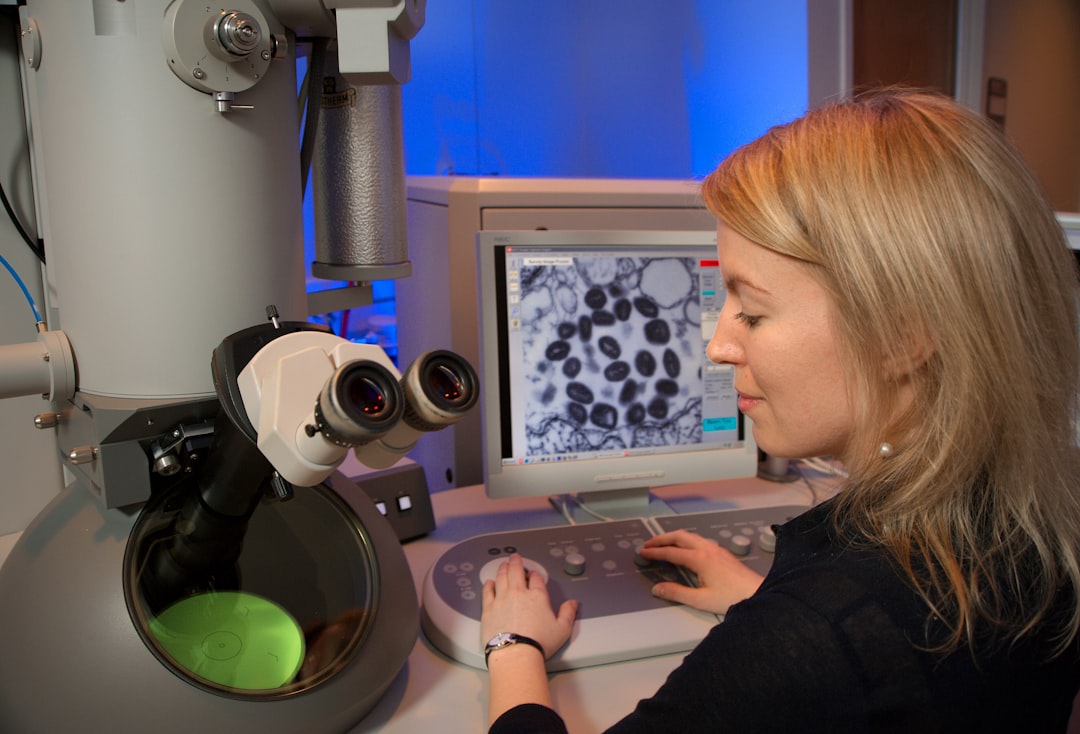

Featured Image

Photo by Maël BALLAND on Unsplash

Why is it important?

This work tries to define the fundamental concepts of different phases of Titanium dioxide with varying percentages of Aluminium to form an alloy. Also, the variation of Micro-Vickers hardness became an important factor to consider for the 'gamma' phase of titanium aluminide alloy.

Perspectives

The work is just to focus on the basic approach towards understanding the hardness variation with the absence and presence of homogenization process of gamma-TiAl alloys.

Anandarup Bhattacharyya

Chonbuk National University

Read the Original

This page is a summary of: Experimental study on the morphology and hardness variation of TiAl alloy at different heat treatment cycles, Materials Today Proceedings, January 2021, Elsevier,

DOI: 10.1016/j.matpr.2021.05.257.

You can read the full text:

Contributors

The following have contributed to this page