What is it about?

Use of magnesium powder or ribbon for the desulphurisation of liquid iron is uneconomical since it involves the production of the metal using energy, then cooling it to ingots, which entails a loss in the process. In situ generation of magnesium uses the sensible heat in the hot metal for producing magnesium vapour directly inside the bath, for desulphurisation. There is no loss of metal. This proces sis more economical compare dto teh conventional desulphurisation process.

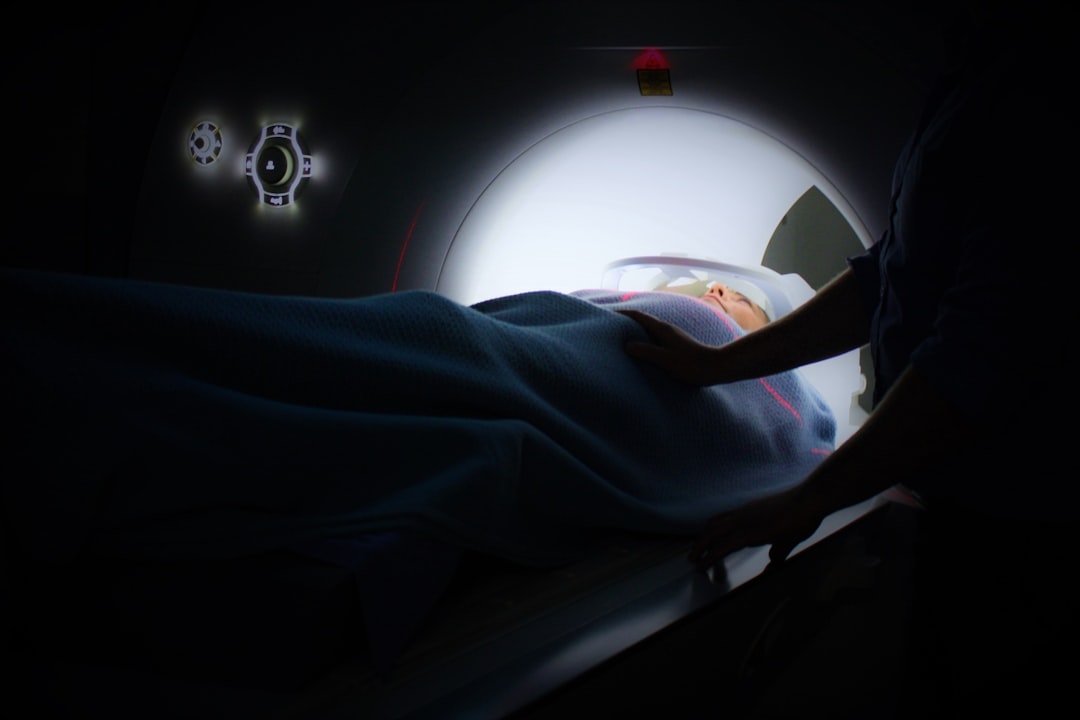

Featured Image

Why is it important?

This process will considerably reduce the cost of desulphurisation. The device developed can be used for injecting magnesium vapour into liquid iron bath for producing iron-magnesium alloys, also.

Read the Original

This page is a summary of: Desulfurization of Hot Metal Through In Situ Generation of Magnesium in 30‐kg Molten Iron Bath‐Influence of Inert Gas Flow Rate, steel research international, December 2013, Wiley,

DOI: 10.1002/srin.201300374.

You can read the full text:

Contributors

The following have contributed to this page