What is it about?

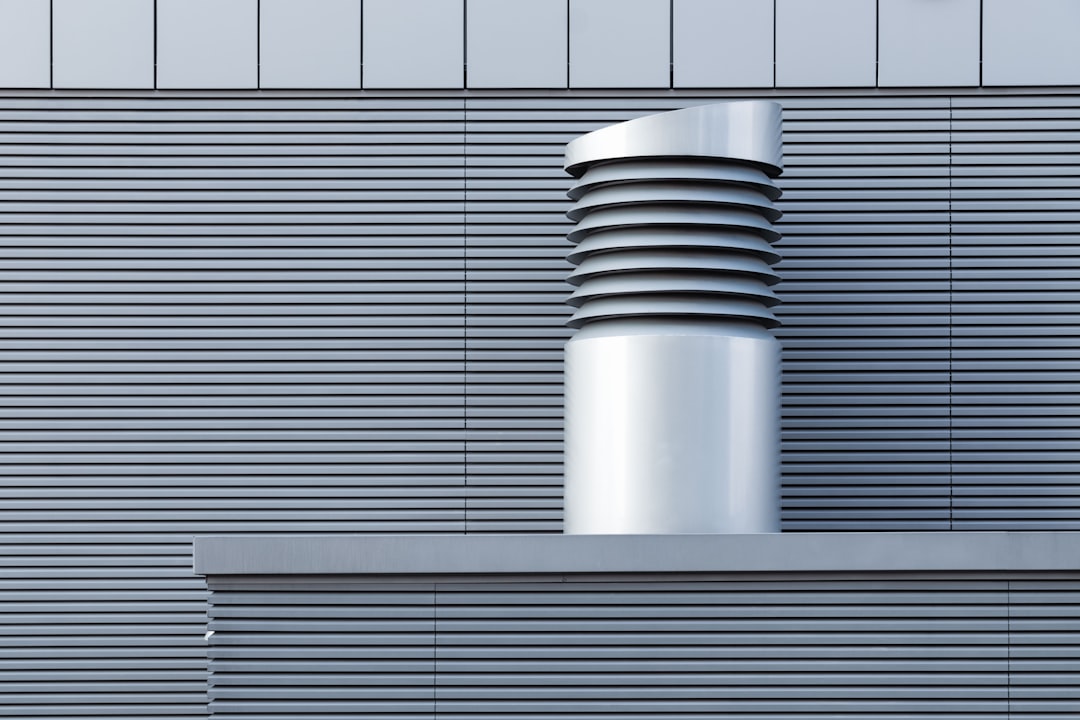

Polymer fibers are typically fabricated by electrospinning. But the process is slow and requires high voltage equipment. Polymer solution blowing or air-brushing is another method allowing for sub-micron fiber fabrication. Fibers are simpler and less expensive (you can buy paint spray and do it) to fabricate and safer (no need for electricity) to operate. However commercial air-brushes, although inexpensive and readily available, appear not to be the best for providing control over fiber fabrication. Our results indicate that quality of fiber mats was higher (less number of polymer beads) when using a simple custom built air-brush. So, use a commercial air-brush if you want to just try out the technique. If you want to get some quality fiber mats, try to build your own air-brush or contact us so we can help you.

Featured Image

Why is it important?

For anyone who would like to control polymer fiber fabrication and to obtain some reproducible fiber mats, custom built air-brush is the way to go. More useful for bio-tech and material research.

Perspectives

I hope that readers/researchers can find this article very practical. In the article, there is also some basic polymer characterization and theory which hypothesizes how fibers formed.

Dr Wojtek Tutak

ADA Foundation

Read the Original

This page is a summary of: Rapid polymer fiber airbrushing: Impact of a device design on the fiber fabrication and matrix quality, Journal of Applied Polymer Science, August 2015, Wiley,

DOI: 10.1002/app.42813.

You can read the full text:

Contributors

The following have contributed to this page