What is it about?

In this study, we report on a promising method for achieving ‘solvent-free' dispersion of cellulose nanocrystals (CNCs) into polyether polyol for the production of RPUF. This was achieved through wet grinding of CNC powder in polyol in an agitator bead mill and the dispersion of CNCs in polyol was superior to classical ultrasonication.

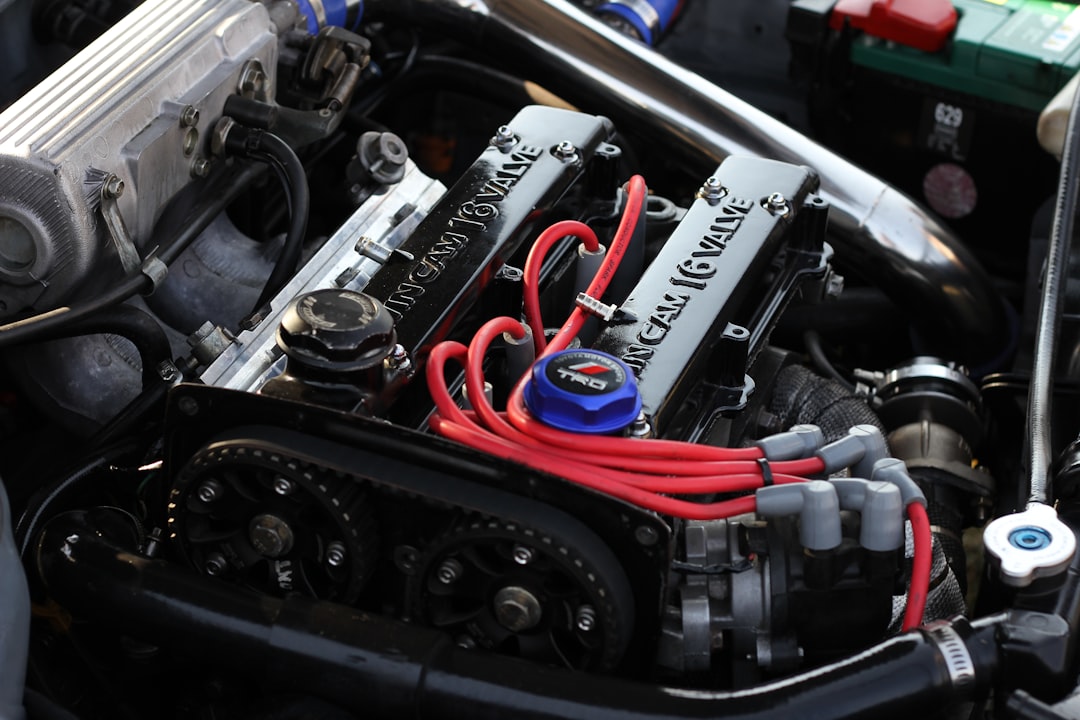

Featured Image

Photo by Ömer Haktan Bulut on Unsplash

Why is it important?

Nanocellulose is explored as an eco-friendly cell modifier and reinforcer for improving the thermal insulation and mechanical performance of rigid polyurethane foam (RPUF). Research Highlights Enhanced properties of polyurethane foam using well-dispersed nanocellulose. Superior dispersion of nanocellulose in polyol using agitator bead mill. Involvement of zirconium for tuning microstructure of polyurethane foam.

Perspectives

While the improvements (reduction) in thermal conductivity, due to the nucleation effect of CNCs, in the RPUF from the milling method is comparable to that from the ultrasonication method, it should be noted that it was achieved despite of a reduction in closed cell content (~80%) and at a similar average cell size. This effect has been attributed to either superior dispersion quality of the milling method and/or involvement of a zirconium impurity within the CNC-RPUF.

Dr Pratheep K Annamalai

University of Queensland

Read the Original

This page is a summary of: Tuning the microstructure of polyurethane foam using nanocellulose for improved thermal insulation properties through an efficient dispersion methodology, Polymer Composites, September 2023, Wiley,

DOI: 10.1002/pc.27743.

You can read the full text:

Resources

Contributors

The following have contributed to this page