What is it about?

The safe service of concrete structures is very important. The coating can provide both protection and long-term health monitoring of existing facilities. However, as a cement-based monitoring coating, conductivity, cost, operability and other challenges exist. Through a series of molecular modifications, we prepared the originally expensive components with cheap industrial-grade products, realizing the industrial production and wide application of coatings.

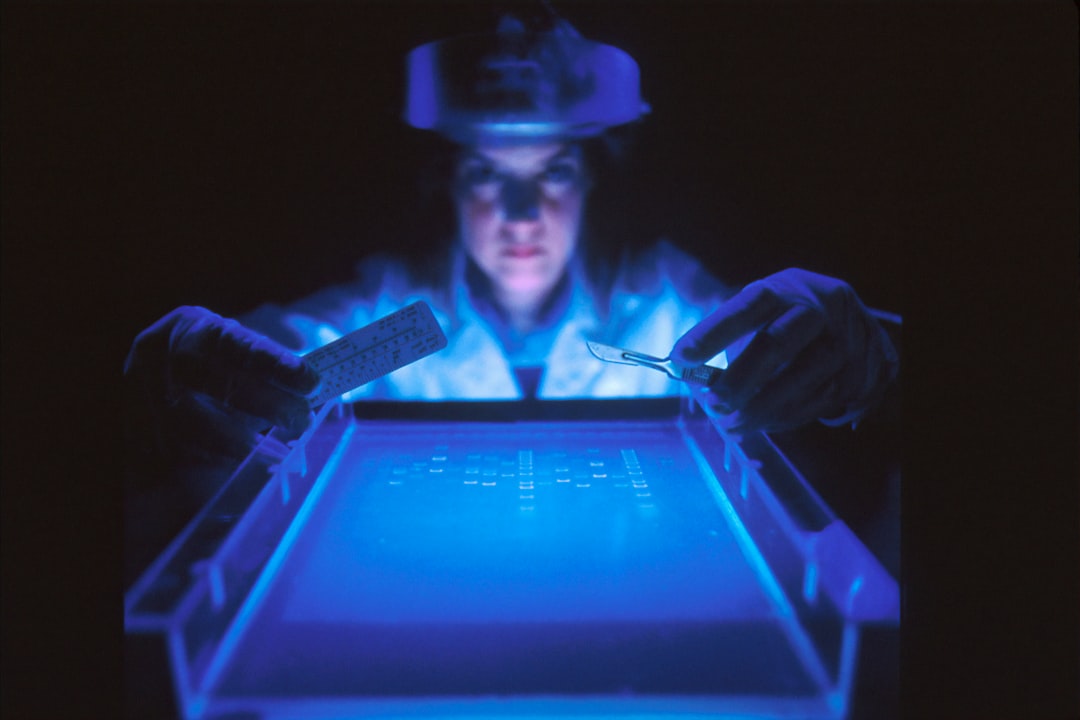

Featured Image

Photo by Abraham Barrera on Unsplash

Why is it important?

We found that the muscle-like IPN increases the cement-based coatings’ maximum deflection angle to 30° and improves the monitoring accuracy of compressive, tensile and fatigue micro-changes of concrete structures to more than 95%. The POSS···Ca2+···C-S-H interaction in C-POSS partially transferred the intra-adhesive hydrogen bonds surrounding the nano-conductor into electrostatic bridging ones to maintain an excellent electromechanical conductive dispersion.

Perspectives

This paper presents a pioneering work by developing a novel waterborne epoxy resin-modified cement-based composite as a coating sensor. Such developed resin-modified cement-based composite coating sensor can solve the difficulty of dispersion that is often encountered in the preparation of cement-based sensors made with nanoscale carbon materials. The proposed composite coating presents high flexibility and excellent strain and damage sensing capacities. More importantly, applying cement-based sensors in the form of coating is the most viable and beneficial for practical engineering considering the application flexibility, high cost of the carbon nanofillers, and the challenge of massive on-site production, hence this work is highly valuable and should benefit the field application of cement-based sensors. Then this work assessed the bonding strength, fire resistance, freeze-thaw erosion resistance and corrosion resistance of the coating sensors on concrete substrates, which were crucial performances that should be appropriately valued to assure the long-term application of the sensor coating in a real field environment and were merely studied previously.

Bo Pang

Qingdao University of Technology

Read the Original

This page is a summary of: Ultraductile Cementitious Structural Health Monitoring Coating: Waterborne Polymer Biomimetic Muscle and Polyhedral Oligomeric Silsesquioxane‐Assisted C‐S‐H Dispersion, Advanced Functional Materials, October 2022, Wiley,

DOI: 10.1002/adfm.202208676.

You can read the full text:

Contributors

The following have contributed to this page